The Knives

David at work on the New Warther Pocket Knives Today

Model 1923 with ivory handles under construction

-1.jpg)

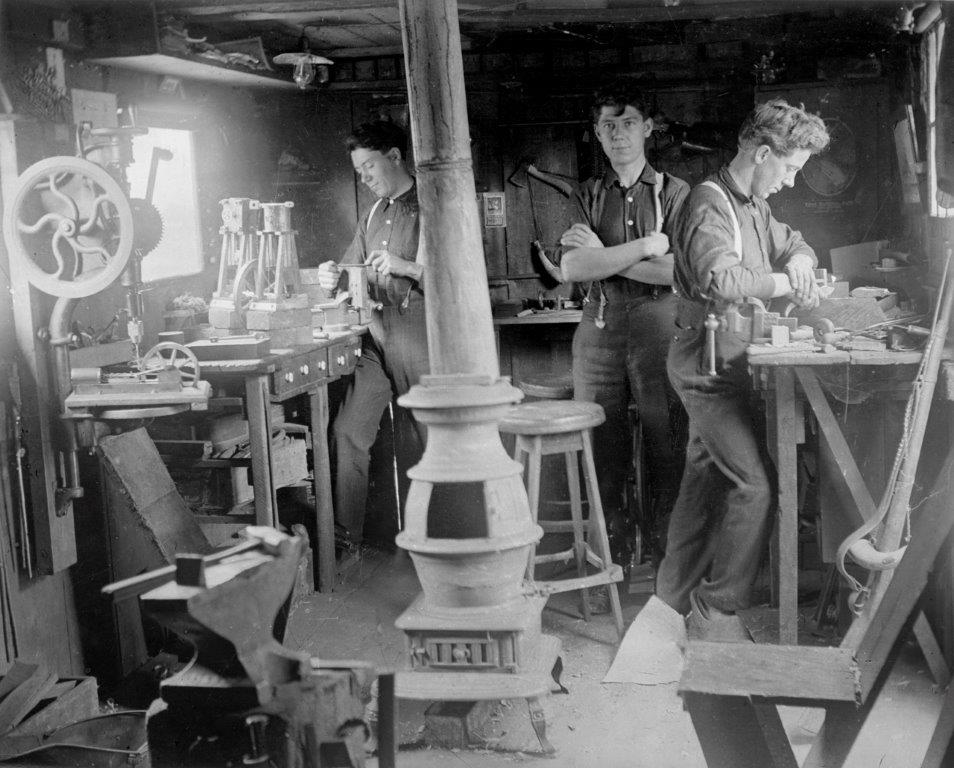

My Father Dave (Front left), My Grandfather Mooney (Center) and my uncle Tom Warther.

Working in the Warther knife shop circa 1950.

The original workshop for carving and knife making

Dover, Ohio circa 1907

Original Mooney Warther pocket knives

How We Began Again

Dear Folks,

When I started thinking a few years ago about bringing the Warther pocket knife back into limited production I was faced with many challenges and with several important decisions. It became my objective to be true to the knife itself - the knife grandpa envisioned, designed and made, starting in 1905. I decided I would only make improvements if they did not alter the knife and its core personality.

As an example, I decided to make the blade and back spring of 1095 tool steel. This was my dad's favorite knife steel and it was nearly identical to the steel grandpa forged himself over a century ago for the first Warther pocket knives. Modern metallurgists have discovered that cryogenic quench treatment of this steel creates a molecular compactness within the material itself that makes this time honored steel stronger. This treatment also gives the steel better edge holding properties for a knife. We do this cryogenic treatment as it improves the knife without detracting from the knife. As with dad and grandpa, the blades are then tempered to 58-60 Rockwell on the C scale and the back springs to 45 Rockwell.

Alternately, I have been encouraged to improve the knife by implanting a miniature ball bearing for the blade pivot. This and several other suggested ideas would improve the knife, in a sense, but such innovations would alter the knife to where it would no longer be the Warther knife that has been with us for over 100 years. Warther knives have a certain "walk and talk" - an old knife maker's term for how the blade feels while being opened and closed. The bearing would have changed all of that and the knife would have felt different. No bearings. No bells and whistles - just a good solid Warther pocket knife.

As you look at each model on this site you will learn of how the handle material of each knife model correlates to a year and era in grandpa's life and in the design of the knife. The boxes we make to hold the knives are made of a species of wood that also correlates to the model number and hence the year.

Where possible I have improved the accuracy of the fitting of the handle, bolsters and other fitted parts with the use of more precise equipment than dad or grandpa had in their shops and yet the majority of the work is in hand grinding and polishing with the same tools and limited technology they had.

The bolsters are made of nickel silver. This has been the traditional bolster material since these knives were first made over a century ago - Dale, dad and grandpa very seldom used anything else. Nickel Silver, also known as German Silver, is a very tactile material that holds a warmth, a specific feel and an alluring weight that speaks well to the holder. Nickel Silver retains an old world medieval depth of character that lets you know it is not stainless steel. This look and feel is an earmark of the Warther pocketknife.

I have improved the knife and I have allowed it to remain unchanged at the same time. I would like to think that grandpa, dad and Dale would all approve. We hope you do as well.

Changes and improvements and yet you are holding a Warther knife.

Sincerely,

David Warther II

Model 1910

Model 1910 Natural White Bone

$ 700.00 SOLD OUT

Model 1910 Tyrian-Phoenician Purple Bone

$ 700.00 SOLD OUT

Model 1910 Red Ochre Bone

$ 700.00 SOLD OUTDavid Warther Knives Model 1910

In 1905, at age 20, Ernest Warther designed and made his first pocketknife. By 1910 he had refined and solidified the unique Warther pocketknife design and was utilizing North American cattle bone as the handle material.

Today the Model 1910 comes in a variety of different colored bone handles crafted from North American cattle bone. Bone has its own look and feel and is pleasant to the touch.

The bolsters and liners are of Nickel Silver. This has been the traditional bolster material since these knives were first made over a century ago. Nickel Silver, also known as German Silver, is a very tactile material that holds a warmth, a specific feel and an alluring weight that speaks well to the holder.

Nickel Silver retains an old world medieval depth of character that lets you know it is not stainless steel. This look and feel is an earmark of the Warther pocketknife.

The box that holds all of our knives is in the shape of the earliest Egyptian ships to reflect my work in carving the history of the ship. The box for the Model 1910 is of maple - one of the two primary woods grandpa carved with in 1910.

Click on a photo to the left for more photos and detailed information.

The knife is 6.75" long unfolded. It is 3.75" long folded and has a 3 inch blade.

Model 1923

Model 1923 Pre-Ban Elephant Ivory

for Ohio Customers Only

$ 800.00 Order Online

Model 1923 Ancient Mammoth Ivory

Legal to ship anywhere except to the US states of NY, NJ, CA, HI, NV or IL.

$ 800.00 Order OnlineDavid Warther Knives Model 1923

In 1923 Mooney began traveling his steam locomotive carvings with major railroad companies and later by exhibit trucks. This promotional work was lucrative and he was now making his pocket knives with ivory handles. In the roaring 20's Mooney's ivory handled pocket knives were well sought after.

Today, the Model 1923 is being made with pre-ban elephant ivory for Ohio customers and ancient ivory handles from ancient fossilized mammoth tusks. Pre-act elephant ivory, per federal regulation 50 CFR 17.40(e), cannot sell outside the state of Ohio. Fossil mammoth ivory can sell internationally and to all states except NY, NJ, CA, HI, IL and NV per state law in those states.

Click on a photo to the left for more photos and detailed information.

The bolsters and liners are of Nickel Silver. This has been the traditional bolster material since these knives were first made over a century ago. Nickel Silver, also known as German Silver, is a very tactile material that holds a warmth, a specific feel and an alluring weight that speaks well to the holder.

Nickel Silver retains an old world medieval depth of character that lets you know it is not stainless steel. This look and feel is an earmark of the Warther pocketknife.

The box that holds the knife is in the shape of the earliest Egyptian ships to reflect my work in carving the history of the ship. The box for the Model 1923 is of walnut - a wood grandpa carved exclusively from in 1923.

Click on a photo to the left for more photos and detailed information.

The knife is 6.75" long unfolded. It is 3.75" long folded and has a 3 inch blade.

Model 1938

David Warther Knives Model 1938

By 1930 the depression had impacted the life of Mooney as it had everyone in America. With customers no longer being able to afford ivory, a decade long series of ebony handled knives were made with many being made between 1938 and 1941.

The Model 1938 today is fitted with ebony wood handles.

The bolsters and liners are of Nickel Silver. This has been the traditional bolster material since these knives were first made over a century ago. Nickel Silver, also known as German Silver, is a very tactile material that holds a warmth, a specific feel and an alluring weight that speaks well to the holder.

Nickel Silver retains an old world medieval depth of character that lets you know it is not stainless steel. This look and feel is an earmark of the Warther pocketknife.

The box for the Model 1938 is of oak - a wood identified with strength. Grandpa was enduring the depression and dad was growing up in it - they had the strength every American had at the time to make it through those tough years.

Click on the photo to the left for more photos and detailed information.

The knife is 6.75" long unfolded. It is 3.75" long folded and has a 3 inch blade.

Model 1963

Model 1963 Paua Abalone Pearl

$ 900.00 Order Online

Model 1963 Select Green Abalone Pearl

$ 900.00 Order OnlineDavid Warther Knives Model 1963

In 1963, at age 78, Ernest made his last pocketknife. It was number 500 and it had handles made of abalone pearl.

It was in these later years that the Warther pocketknives, made by Mooney (1885-1973) and son Dave (1926-2011), were often made with abalone and mother of pearl handles. When Dave's oldest son Dale (1952-2010) began making pocketknives in the 1970's he continued with a focus of utilizing pearl handle material.

Today, the Model 1963 is fitted with a variety of different pearl handle material including abalone and Mother of Pearl.

The bolsters and liners are of Nickel Silver. This has been the traditional bolster material since these knives were first made over a century ago. Nickel Silver, also known as German Silver, is a very tactile material that holds a warmth, a specific feel and an alluring weight that speaks well to the holder.

Nickel Silver retains an old world medieval depth of character that lets you know it is not stainless steel. This look and feel is an earmark of the Warther pocketknife.

The box for the model 1963 is of wild cherry. When dad built the first museum in 1963, in Dover Ohio, the wood work in the building was done in wild cherry and I continued with that idea when I built the New Warther Museum in 2013 in Sugarcreek, Ohio.

Click on a photo to the left for more photos and detailed information.

The knife is 6.75" long unfolded. It is 3.75" long folded and has a 3 inch blade.